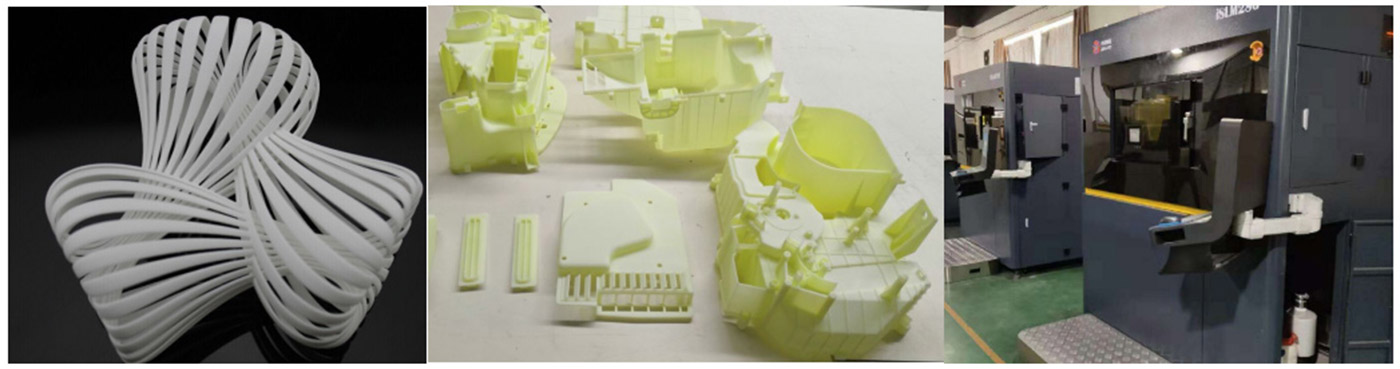

SLA (StereoLithography)

• Tlhaloso: SLA ke theknoloji ea ho folisa ea foto, e bolelang mokhoa oa ho etsa lera le nang le mahlakore a mararo ka lera ka karabelo ea polasetiki ea lehoakhoa la photosensitive ka radiation ea ultraviolet. Sengoathoana sa mosebetsi se lokiselitsoeng ke SLA se na le ho nepahala ho phahameng 'me ke theknoloji ea pele ea khatiso ea 3D ea khoebo.

• Ea khatiso Material: Photosensitive lehoakhoa

• Matla: lehoakhoa la photosensitive ha le lekane ho thatafala le matla mme le robeha habonolo. Ka nako e ts'oanang, tlasa maemo a phahameng a mocheso, likarolo tse hatisitsoeng li bonolo ho koba le ho holofala, 'me matla a ho jara ha a lekana.

• Likarolo tsa sehlahisoa se felileng: Lisebelisoa tsa SLA tse hatisitsoeng li na le lintlha tse ntle le bokaholimo bo boreleli, bo ka mebala ka pente ea spray le lits'ebetso tse ling.

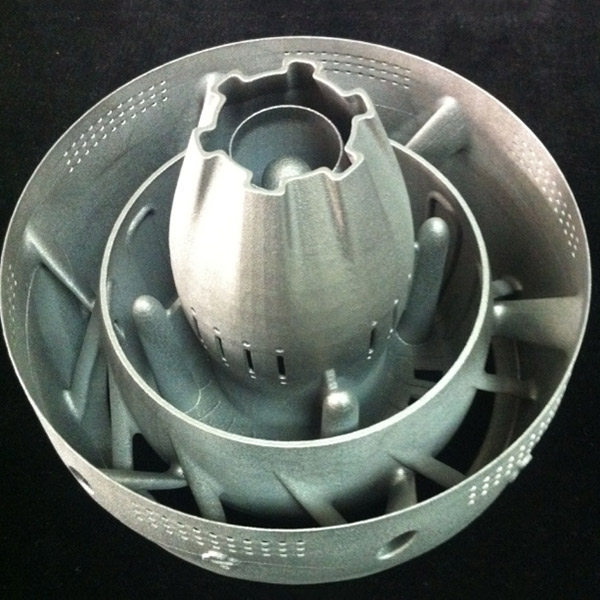

Laser Sintering e khethiloeng (SLS)

• Tlhaloso: SLS ke mahlale a khethollang a laser sintering, a ts'oanang le mahlale a SLM. Phapang ke matla a laser. Ke mokhoa o potlakileng oa ho itšireletsa o sebelisang laser ea infrared e le mohloli oa mocheso ho sinter lisebelisoa tsa phofo le ho theha likarolo tse tharo tsa likarolo ka lehare.

• Lintho tsa khatiso: Phofo ea Nylon, phofo ea PS, phofo ea PP, phofo ea tšepe, phofo ea ceramic, lehlabathe la lehoakhoa le lehlabathe le tlotsitsoeng (lisebelisoa tse tloaelehileng tsa khatiso: nylon phofo, nylon le fiber ea khalase)

• Matla: ts'ebetso ea lisebelisoa e molemo ho feta lihlahisoa tsa ABS, 'me matla le ho tiea li ntle haholo.

• Likarolo tsa sehlahisoa se felileng: sehlahisoa se feliloeng se na le litšobotsi tse phahameng haholo mme se loketse tlhahiso e tobileng ea mehlala ea litekanyo, mefuta e sebetsang le sehlopha se nyane sa likarolo tsa polasetiki. Bothata ke hore ho nepahala ha ho phahame, bokaholimo ba sebopeho bo batla bo le bobe, 'me ka kakaretso ho hlokahala hore bo bentšitsoeng ka letsoho, bo fafatsoe ka lifaha tsa khalase, molora, oli le tse ling tsa ts'ebetso ea morao-rao.

CNC

• Tlhaloso: Mechini ea machining ea CNC ke mokhoa oa ho etsa o tlosang thepa moo sesebelisoa sa taolo ea software se fanang ka litaelo ho etsa sesebelisoa se etsa mehato e fapaneng e hlokahalang. Ts'ebetsong ena, lisebelisoa tse fapaneng tse nepahetseng li sebelisoa ho tlosa lisebelisoa tse tala le ho etsa likarolo kapa lihlahisoa.

• Lisebelisoa: Lisebelisoa tsa ts'ebetso ea CNC li pharalletse haholo, ho kenyeletsoa le li-plastiki le tšepe. Lisebelisoa tsa letsoho la polasetiki ke: ABS, acrylic / PMMA, PP, PC, PE, POM, nylon, bakelite, jj .; Lisebelisoa tsa tšepe tsa letsoho ke tsa tšepe: aluminium, aluminium Magnesium alloy, aluminium zinc alloy, koporo, tšepe, tšepe, jj.

• Matla: lisebelisoa tse fapaneng li na le matla a fapaneng mme ho thata ho li thathamisa

• Likarolo tsa sehlahisoa se felileng: Likarolo tsa machining tsa CNC li na le bokaholimo bo boreleli, ho nepahala ho tlholetseng, 'me khokahano e ntlehali,' me ho na le likhetho tse fapaneng tsa kamora ho sebetsa.

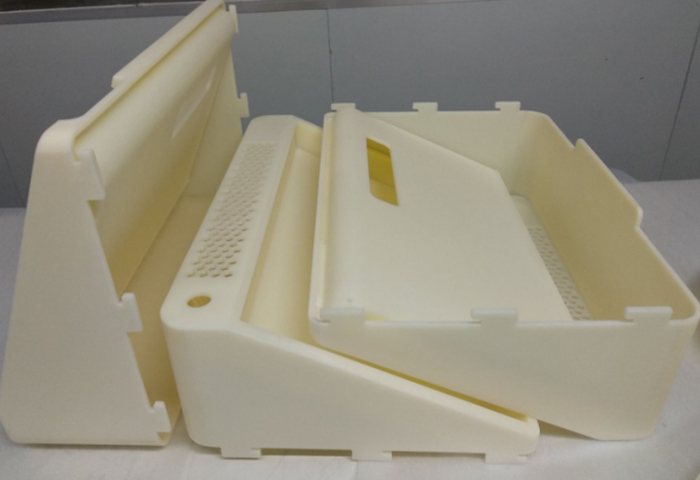

Lahla lephaka

• Tlhaloso: Theknoloji ea ho lahla lephaka ke ho sebelisa mofuta (likarolo tse potlakileng tsa prototyping, likarolo tsa letsoho la CNC) ho etsa hlobo ea silicone tlasa boemo ba vacuum. E boetse e sebelisa PU, ABS le lisebelisoa tse ling ho e tšela, ho etsa kopi e tšoanang le mofuta oa sehlahisoa.

• Lintho tse bonahalang: Abs, Pu, PVC, silicone, bonaletsang Abs

• Matla: matla le thatafalo li tlase ho feta likarolo tsa letsoho la CNC. Lintho tse tloaelehileng tsa PU li batla li robehile, ho ba thata le ho hanyetsa mocheso ka bongata li futsanehile. ABS e na le matla a phahameng, polasetiki e ntlafetseng, le ts'ebetso e bonolo ea morao-rao.

• Likarolo tsa sehlahisoa se felileng: ho bonolo ho nyenyefatsa le ho holofala; ho nepahala ka kakaretso ke 0.2mm feela. Ho feta moo, lephaka lahla likarolo tsa letsoho li ka hanela feela mocheso o phahameng oa likhato tse ka bang 60, mme e tlase ho feta likarolo tsa letsoho la CNC ka matla le ka thata.

Theknoloji ea ho lahla e sebelisa leqhubu la sehlahisoa ho etsa hlobo ea silicone tlasa maemo a lephaka, mme e amohela lisebelisoa tse joalo ka PU, ABS jj ho etsa likarolo tlasa maemo a lephaka a ts'oanang le mohlala oa sehlahisoa. Mokhoa ona o loketse tlhahiso e nyane ea methapo Ke tharollo e theko e tlase ea ho rarolla tlhahiso ea liteko le tlhahiso e nyane ea batch nakong e khuts'oane, hape e ka fihlela tlhahlobo ea ts'ebetso ea mehlala e meng ea boenjineri e nang le sebopeho se rarahaneng. Ka kakaretso, theknoloji ea ho lahla lephaka e loketse tlhahlobo e bonolo le litlhoko tsa moralo oa mohopolo.

Melemo ea Prototyping e Potlakileng

• Tekanyo e phahameng ea boiketsetso molemong oa ho etsa

• Phetolelo e nepahetseng ea setheo

• Phahameng tlhakore ho nepahala. Tlhakole tlhakore ka ba ho fihlela ho ± 0.1mm

• Boleng bo holimo ba bokaholimo

• Sebaka se sa lekanyetsoang sa moralo

• Ha ho hlokahale kopano

• Lebelo la ho etsa kapele le nako e khuts'oane ea ho fana

• Ho boloka lisebelisoa tse tala

•Ke ntlafatsa moralo oa sehlahisoa