Die Casting

Pressure die casting is a precise casting method. The general camera, typewriter, electronic calculators, decorations, as well as the complex parts of some transportation vehicles are mostly made by die casting.

The advantage of die casting includes the excellent dimensional accuracy. Compared with other casting processes, its surface is smooth and can directly cast high strength sections within the structure.

Tooling Steel

The H13 steel, after a heat treatment, performs well enough to withstand the huge casting pressure. The tooling lifetime volume is up to 30,000 shots and can definitely meet your low to medium production part requirements.

Casting Metal

Aluminum Alloy ADC 12, A380, and Zinc #3 are three popular materials for casting. Furthermore, we can cast parts in Zinc #5, A360, ADC10, as well as other metals. You can choose the metal’s properties that will best suit your product’s needs.

Post Finish

We offer a series of post finishing services for die casting parts.

The finish includes painting, electroplating, printing, powder coating, anodizing, sand blasting, E-coating, polishing, and passivation.

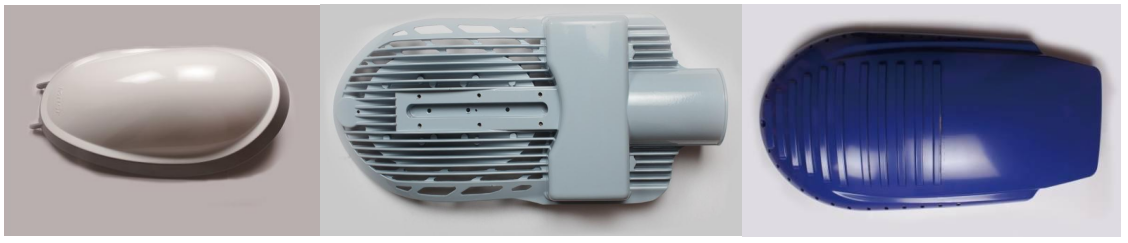

Product Show

Comments from customer: HSR has been dedicating in producing die casting, which are required for high precision, good surface with complex shapes.

PC parts

Sanitary

Car parts

Sun Lighting parts

Plating show

Street LED Light